|

The height of this bench is 38 in., a comfortable working

height for most people. If you prefer a lower work surface, you can

lower the bench. However, be aware that alterations also affect the

dimensions of the table saw module (

Fig.

B

) and the depth of the under-bench drawers (

Fig.

C

), the flip-up assembly table (

Fig.

D

), and the slide-out drawer panel (

Fig.

E

).

The workbench/miter saw table, made entirely from 2x4s and

3/4-in. plywood, is the basic framework for all the other features.

An alcove allows the miter saw to be set below the bench top, making

the miter saw table even with the bench (Fig. A).

That

way, the bench serves as a support table when you're cutting long

stock. To help hold long material square to the saw fence, screw a

2x2 to the bench for an extended fence (

Photo

5

). Miter saw tables vary greatly in height depending on the

brand. Customize the alcove to get the right height. In our design,

a piece of plywood screwed to the underside of the bench creates a

4-1/4 in. deep recess. Measure the height of your miter saw table to

determine how much to shim up the base of the saw to make it even

with the table. If your miter saw table is higher than 4-1/4 in.,

you'll have to shim between the underside of the bench and the

plywood base. Make the miter saw removable for those on-the-road

jobs by installing T-nuts and wing screws.

|

|

| |

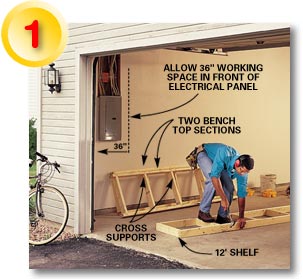

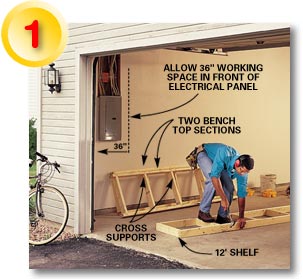

PRECUT the cross supports and rails using the

dimensions given in Fig. A, p. 63. Nail the cross supports to

the rails for the two bench sections and the shelf section

with two 16d nails at each

joint.

|

When

installing the bench framework, don't assume your garage floor is

level. Most likely it's sloped toward the garage door. Draw a level

reference line on the wall (Photo 2) to keep the shelf and

bench level.

|

|

| |

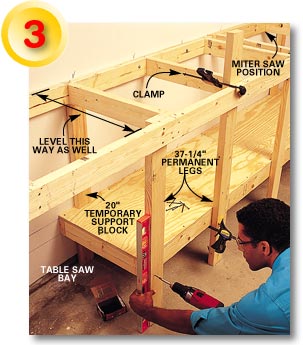

SNAP two level lines at 37-1/4 in. (bench frame

height) and 12 in. (shelf frame height) from the floor the

length of the bench. (Note: Garage floors often slope toward

the door, but the ceiling or top framing is level.) Begin your

layout on the wall on the end of the bench that's farthest

from the door. Rest the shelf framing sections on the

temporary support blocks, and clamp temporary 4-ft. legs to

the front of the framing, holding the shelf level. Bolt the

rear 2x4 to every wall stud with a 3-1/2 in. x 1/4-in. lag

screw.

|

|

|

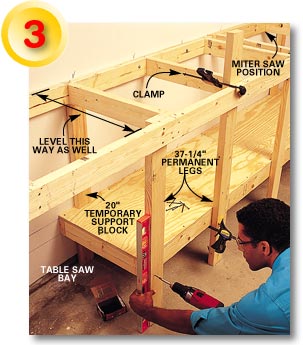

| |

SCREW 3/4-in. plywood to the framing of the

lower shelf with 1-5/8 in. screws. Tack two 20-in. long

temporary support blocks to the wall on top of the shelf

plywood. Rest the bench frame on the supports, level it and

clamp the front rail to the temporary support legs. Plumb the

permanent legs and screw them into the front of the shelf rail

and into the backside of the bench rail with four 3-in.

screws. Add the 2x4 angle brace shown in Fig. A. Screw

the plywood to the bench top, leaving the miter saw bay

open.

|

|